Speeds, Feeds, RPM and Depth Per Pass. Starting points for wood on a STEPCRAFT CNC System

We get a lot of questions from customers asking about the optimal speeds and feeds, RPM and depth per pass for STEPCRAFT machines when working with wood. Like with many things related to CNC, there is a lot of trial and error to find the optimal settings for your given machine, material and bit (end mill) that you are using. There are speed and feed calculators on the market and online, but many times, they will over complicate the process, especially when you are working with wood. In this article, I want to talk about some good starting points that you can use as a basis of making your first successful cuts in wood on your STEPCRAFT CNC.

A couple things that we need to go over first.

- If you are using a STEPCRAFT Version 1 machine, then you need to know that you maximum feed rate is 30 mm/sec

- If you are using a STEPCRAFT-2 machine, then your maximum feed rate is 50 mm/sec

- Note the number of flutes on your end mill as well as the type of flutes (up spiral, down spiral, straight, compression, etc). A 2 flute up spiral will have different settings than a 2 flute compression or down spiral. So you want to make note of this, especially if you intend to save the tool information as suggested below.

It is important to know these values so you do not set the software to exceed them – you can not force the machine to go any faster than it is capable of.

Also, these values that I am giving below are just a starting point. You will have different results depending on the spindle you are using, the number of flute in the bit and style of bit.

In the Vectric programs, you will select a tool from the tool database. The screen will look like this:

NAME – This is where you can specifically name your tool. I always use the format shown – type of tool (diameter). You can also add on the type of material that this tool is for. You will, over time, figure out the optimal settings for various materials that you use and you could name this tool for that material so you do not have to go through this process each time. For instance, I could name this tool “End Mill (0.125″) MDF” and the next time I run MDF I can choose this tool and know my settings are correct.

GEOMETRY – This is where you would enter the diameter of the tool and choose “inches” or “mm”

CUTTING PARAMETERS

- PASS DEPTH – For wood, my rule of thumb is to always make this number 1/2 the diameter of the tool. So in this case of a 0.125″ (1/8″) end mill, I set the pass depth to 0.0625″ (1/16″). Depending on the wood you are cutting, you might be able to increase this. Pine, for example, cuts well at 0.125″ (1/8″) deep whereas Oak works well at 0.0625″ (1/16″). NOTE: As a general rule, you should not exceed the diameter of the tool as it can put undo stress on the machine, spindle and tool. The only exceptions to this would be for very light material like foam or Balsa wood.

- STEPOVER – This setting is used in pocketing; when you remove material between vectors. If you think of stepover like mowing a lawn. When you make one pass, you slightly overlap the previous pass to ensure that you are not leaving a small strip of grass uncut. Stepover is the same thing, it refers to the amount of overlap there is between passes. 40% is the default which is good for most general pocketing and roughing passes (when carving 3D objects). When making finish passes, you would reduce this number to 10%, especially when using a 1/16″ ball nose end mill for detail carving. It will give you the best finish results.

FEEDS AND SPEEDS

- SPINDLE SPEED – If you are using a STEPCRAFT HF-500 spindle, then this number would control the RPM. If you are using a Dremel or a router such as the Dewalt DW611, or a KRESS, then this number will not have any effect on the job. A good rule of thumb for RPM (when using the HF500) is to keep the setting at 15,000 rpm or higher for cutting woods. You will have more cutter speed which will make the tool cut easier and should provide a better finish. There is no reason to run at full speed though. Doing so just makes the spindle spin excessively fast.

Finding the optimal RPM – You can listen to the spindle as it is cutting. If it sounds like it is straining or chattering then increase the RPM. To determine if you are spinning too fast, you can lower the RPM until you hear it bog a little and then increase it until there is no RPM sound variance while cutting.

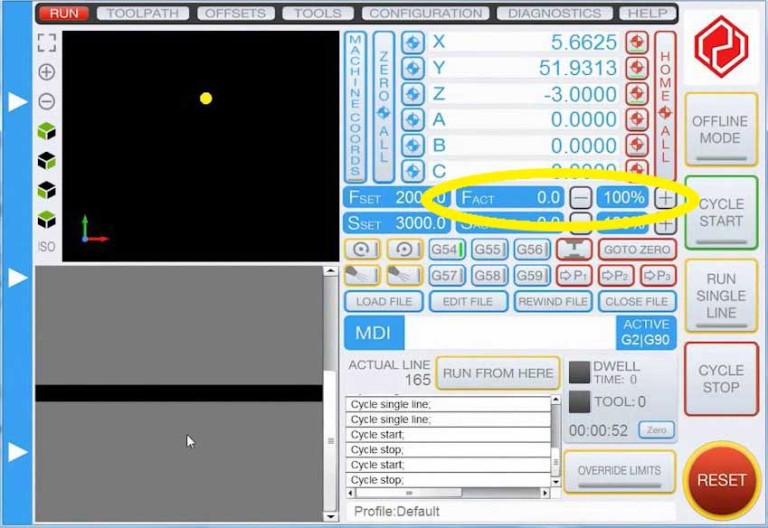

- FEED RATE – When cutting woods on a STEPCRAFT, I always suggest setting this to 1/2 of the maximum machine feed speed. So for a Version 1 machine, this will be set to 15 mm/sec and for a version 2 machine, you will set this to 25 mm/sec. Once the job is running you can increase this feed rate by adjusting the F act in UCCNC. When you reach 200% you will be at full speed of the machine.

Finding the optimal Feed Rate – I always start a job and then listen to the spindle and the bit. I want to listen for chatter on the bit or straining on the spindle. If you hear either, then lower the F act in UCCNC until it sounds better. If it sounds effortless then you can increase the feed rate until you hear any signs of straining or chatter. Once you reach 200%, you are at the full speed capacity of the machine. If you reach this and it still sounds effortless, then you can go back into the tool settings for this material and increase the depth per cut,

leaving the feed rate at 25 mm/sec. Then you would start the process all over with the new depth per cut.

As an example, if I made it to 200% at 0.0625″ (1/16″) and it sounded good, then I would increase my Pass Depth to 0.125″ (1/8″) and try cutting that material again. I would continue to adjust the speed until it sounds like it is straining then back off 10%. So if I was able to get to 150% before I noticed any strain, then I will go back into the tool settings and change the speed to 37 mm/sec and rename that tool for that material. So the time I cut that same material I can just choose that tool and these setting are optimized (providing I am using the same tool with the same number of flutes).

As a final rule of thumb, I try not to run the machine past 45 mm/sec. The stepper motors will have more torque at lower speeds and running at max speed can increase the changes that you lose steps during a job if, for instance, you run through a knot in the wood which will be harder to cut. Lower feed rates will have more torque.

PLUNGE RATE – This is the speed at which the bit enters the wood. Keep in mind that End Mills are meant to cut from the side whereas drills are meant to cut vertically. You can not plunge an end mill into material like you would a drill bit. For most woods, I usually set the Plunge Rate to 10 mm/sec or less. However if I use a Ramp of at least one inch, I can increase this. We will discuss Ramps in another post. For now, the best rule of thumb is to keep this at 10 or less.

SUMMARY

If you use this as a guide as you cut and carve wood materials on your STEPCRAFT, you will find the process much simpler to find the optimal cutting speeds.