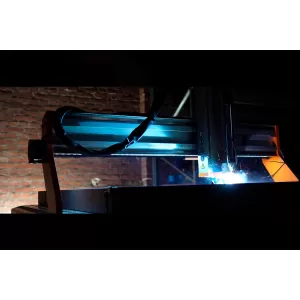

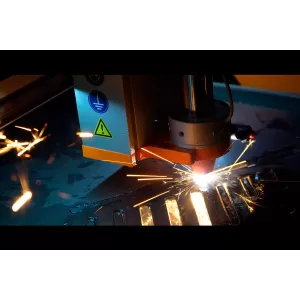

The types of materials you can process on your STEPCRAFT CNC System have just expanded to include: Mild Steel, Stainless Steel, Carbon Steel, Expanded Steel, Aluminum, Copper, Brass, and other ferrous (iron-containing) and non-ferrous materials. STEPCRAFT is the first benchtop CNC system to add plasma cutting capability.

The Plasma Cut 50 delivers a powerful 50 amps of cutting power giving you the ability to cut materials up to 5/8" thick (depending on the material). The Plasma Cut 50 features a high-frequency pilot ignition system giving your jobs clean and accurate pierces and cut quality. The unit can be continuously adjusted between 15 and 50 amps. Additionally, it has active cooling and overheating protection.

The STEPCRAFT Plasma Cutter System comes with everything you need to get started all in one convenient package.

-

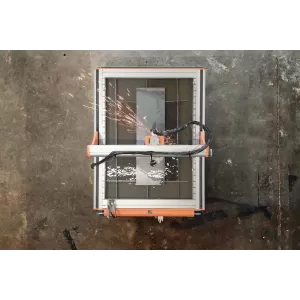

A CNC Plasma Torch and Torch holder are designed to integrate into your STEPCRAFT M-Series CNC system. The Torch Holder is spring-loaded with sensors so it can double as a material touch-off device as well as provide crash detection as the job runs.

-

Our Electronic interface module seamlessly integrates the Plasma Cutter and Torch Holder sensors with your M-Series CNC with the help of the custom Plasma profile for UCCNC which is also included.

-

Due to the possible electronic noise that can be introduced with a plasma system with a high-frequency start, you can not use a USB interface for your STEPCRAFT M-Series CNC. A UC-400 Ethernet interface is included in the Plasma Cutter System to convert your M-Series Interface from USB to ethernet, ensuring that you always have a fast and reliable connection from your computer to your CNC without any disruption from noise.

-

A Water Table is included with replaceable slats to provide cooling of the material as it is being cut as well as to minimize thermal distortion. The material sits on sacrificial steel slats which can be easily replaced as needed based on the amount of cutting you do. The Water Table can be filled by a faucet, hose, or bucket and then a simple drain system is located on the front of the table to quickly drain the water when you want to convert it back to other CNC milling projects.

-

To keep with our commitment to provide our M-Series customers with a complete turn-key system, we include a copy of Sheetcam software with the Plasma Cutter System. This CAM software is one of the most widely used and easiest-to-learn packages on the market for CNC Plasma jobs. Sheetcam allows you to manage a library of settings for various material types and thicknesses so you can quickly go from job to job with the correct settings to yield optimal results.

-

Plasma is a consumable-intensive means of cutting and there are some components on the torch that will wear out over time based on the amount of cutting you do, the settings you use, and the power that you are running your plasma at. The torch tip is the most used consumable. Fortunately, the consumables are very inexpensive and we even start you off with a full consumable kit as part of this system to help you maximize the number of projects you can do right from the start.

REQUIREMENTS

-

30A single phase 220V power (Note: it will NOT run off 110V)

-

Compressed air with at least 4 CFM airflow and a 15 Gallon capacity (30 gallons is preferred)

-

Waterproof work gloves

THINGS TO CONSIDER

While plasma-cutting is going to open up a whole new world of projects and materials that you can process with your STEPCRAFT M-Series CNC system, the plasma process, in general, has some safety concerns to keep in mind.

1) Plasma cutting emits smoke and the cutting process will have sparks as the plasma engages the material, especially as it pierces through the material. Because of this, we recommend that you use the system in a garage or other well-ventilated area that is free from flammable material around the machine.

2) The plasma arc is very bright, similar to a welding arc. It is imperative that you DO NOT look into the plasma flame while it is cutting without wearing eye protection suitable for use with Plasma cutting. A set of safety glasses are included with the system from us.

SYSTEM INCLUDES

-

Plasma Cut 50 IGBT Plasma Cutter

-

CNC Torch

-

Plasma Torch Holder

-

Electronic Interface

-

M.1000 Water Table

-

SheetCam Software

-

Spare Consumables Set

- Supplied with all components necessary for operation

- Integrated modular control electronics for an easy connection to the computer via USB interface resp. via optional parallel or optional Ethernet RJ45 interface

- MDF machine table with aluminum T-slots resp. optional aluminum T-slot table

- Two different machine table heights

- Bosch Rexroth ball bearing guide

- Semi Closed Loop System™

- HIWIN® ball screws

- Flexi Guides™ to securely guide cables and tubes

- Powerful motors Nema 23 (Z-axis: 3A; X- and Y-axis: 4A)

- In-house development of STEPCRAFT aluminum profiles with innovative high rigidity X-profile (registered utility model)

- Standard Ø 43 mm tool holder enables the use of third-party devices (if necessary with adapter)

- Safety brush

- Completely removable machine table

- Freestyle Milling™

- Made in Germany

- 3 years manufacturer's warranty

- Overall Size (X,Y,Z): 1213 x 1624x 646 mm

- Working Space (X,Y,Z): 979 x 1444 x 194 mm

- Clamping Surface (X,Y): 1143 x 1550 mm

- Backlash: < 0.03 mm

- Weight: 137 kg (302.03 lbs)