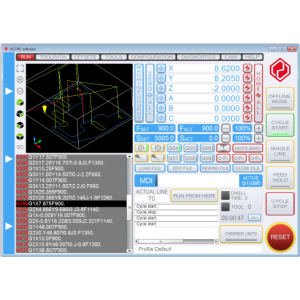

UCCNC is a machine control software. It uses and external hardware to generate signals to produce coordinated motion on up to 6 machine axis. The external hardware is a motion controller device which is currently our UC100 or UC300 or UC400ETH or AXBB motion controller. The License purchases is linked to our range of CNC Drive Motion Controllers listed. One licence per controller of which are none transferable.

This software connects to the external motion controller via a single USB port connection or Ethernet connection (depends on the motion controller model) of a personal computer (PC) and via a software application interface (API) which is built into the software. The installer of the UCCNC software includes and completes all the tasks to make it possible to use this software on your computer. The device drivers are included in the installer too.

Key features:

– Supports the UC100, UC300, UC300ETH and UC400ETH motion controllers

– Controls machines upto 6-axis

– RS274 G and M codes execution

– Unlimited number of user text macros with flexible script engine

– Upto 400kHz operation. (selectable 25kHz, 50kHz, 100kHz, 200kHz, 400kHz with 20us, 10us, 5us, 2.5us and 1.25us pulse widths.) Note: Maximum step frequency depends on the motion controller device used

– Exact stop and cont.velocity interpolations with highly configurable advanced look ahead function

– G54..G59 work offsets and G52/G92 temporary offset

– 3D toolpath viewer

– OpenGL screen optimised for fast screen update rates with low CPU/GPU usage

– Built in visual screen editor

– 48 configurable hotkeys

– 48 configurable inputs trigger to assign physical input pins to UCCNC function calls

– 48 configurable outputs trigger to assign virtual LEDs to physical output pins

– Parametric programming using internal variables and programming mathematical expressions

– Controls THC control for plasma cutters. (M205 and M206 macros)

– Screensets for mills and plasma cutters

– Modbus TCP, RTU and ASCII communication support via Modbus plugin

– M10/M11 macros for fast syncronous outputs for laser cutting applications

– G33 and G76 syncronous thread cutting with free running spindle and encoder feedback to the motion controller

– G33.1 and G33.2 rigid tapping with Z-axis syncronised to spindle motor

– Supports wired MPGs and the UCR200 wireless via plugin

– Built in basic CAM module with DXF files import

– Stopless smooth backlash compensation with adjustable backlash acceleration

– Plugin interface with Visual C# example plugin template. Plugin works with C#, VB, C++ programming languages

– Fast laser scan type engraving plugin, webcamera plugin, Xbox360 controller plugin, 3D printer plugin etc.

– Fast communication with optimised buffering technic producing low button press to event execution time

– Extremely low jitter on the step and direction signals for smooth, high speed and precise motors operation

– Runs in demo (simulation mode) without a software license key

– Compatible OP systems: Windows XP, 7, 8, 8.1,10 on all both 32 and 64bit versions

Download the Product Manual here:

- Supplied with all components necessary for operation

- Integrated modular control electronics for an easy connection to the computer via USB interface resp. via optional parallel or optional Ethernet RJ45 interface

- MDF machine table with aluminum T-slots resp. optional aluminum T-slot table

- Two different machine table heights

- Bosch Rexroth ball bearing guide

- Semi Closed Loop System™

- HIWIN® ball screws

- Flexi Guides™ to securely guide cables and tubes

- Powerful motors Nema 23 (Z-axis: 3A; X- and Y-axis: 4A)

- In-house development of STEPCRAFT aluminum profiles with innovative high rigidity X-profile (registered utility model)

- Standard Ø 43 mm tool holder enables the use of third-party devices (if necessary with adapter)

- Safety brush

- Completely removable machine table

- Freestyle Milling™

- Made in Germany

- 3 years manufacturer's warranty

- Overall Size (X,Y,Z): 1213 x 1624x 646 mm

- Working Space (X,Y,Z): 979 x 1444 x 194 mm

- Clamping Surface (X,Y): 1143 x 1550 mm

- Backlash: < 0.03 mm

- Weight: 137 kg (302.03 lbs)