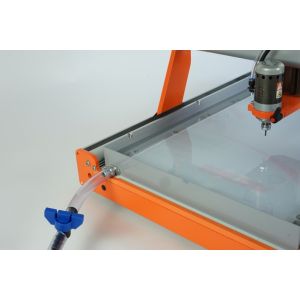

When using the Milling Bath you can machine various materials under water or other liquids.

Thus, you do not only achieve a very good cooling, which is helpful when milling Plexiglas, thermoplastics and carbon, but also a retaining of chips in the bath.

Additionally, the life expectancy of the end mills is extended.

The plates that need to be machined are secured in a comfortable way with the help of clamping bolts.

The Milling Bath is delivered with a mounting kit.

Technical Specifications

Material thickness of the Milling Bath: 1 mm sheet steel Water and corrosion resistant Powder-coated

Maximal plate size (WxL): 150 x 350 mm

Scope of Delivery

Milling Bath with integrated clamping bolt system

Drainage set Ball valve

- Supplied with all components necessary for operation

- Integrated modular control electronics for an easy connection to the computer via USB interface resp. via optional parallel or optional Ethernet RJ45 interface

- MDF machine table with aluminum T-slots resp. optional aluminum T-slot table

- Two different machine table heights

- Bosch Rexroth ball bearing guide

- Semi Closed Loop System™

- HIWIN® ball screws

- Flexi Guides™ to securely guide cables and tubes

- Powerful motors Nema 23 (Z-axis: 3A; X- and Y-axis: 4A)

- In-house development of STEPCRAFT aluminum profiles with innovative high rigidity X-profile (registered utility model)

- Standard Ø 43 mm tool holder enables the use of third-party devices (if necessary with adapter)

- Safety brush

- Completely removable machine table

- Freestyle Milling™

- Made in Germany

- 3 years manufacturer's warranty

- Overall Size (X,Y,Z): 1213 x 1624x 646 mm

- Working Space (X,Y,Z): 979 x 1444 x 194 mm

- Clamping Surface (X,Y): 1143 x 1550 mm

- Backlash: < 0.03 mm

- Weight: 137 kg (302.03 lbs)